Stena Estrid Fast Facts

| IMO number: 9807293 | Built by: AVIC Weihai [CN], W0263, |

| Also known as: | As-built sister-ships: STENA EDDA, STENA EMBLA, CÔTE D' OPALE (part-sister), GALICIA (part-sister), SALAMANCA (part-sister), SANTOÑA (part-sister), STENA ESTELLE (part-sister), STENA EBBA (part-sister). |

| Usual route: Dublin [IE] - Holyhead [GB] | Current operator: Stena Line Irish Sea Ferries, Holyhead |

| Passenger capacity: 1000 (including crew) | Vehicle capacity: 3,100 lane metres of freight (plus 120 passenger cars in their own dedicated garage on deck 7) |

Stena Estrid – The first of Stena’s Next Generation Ferries

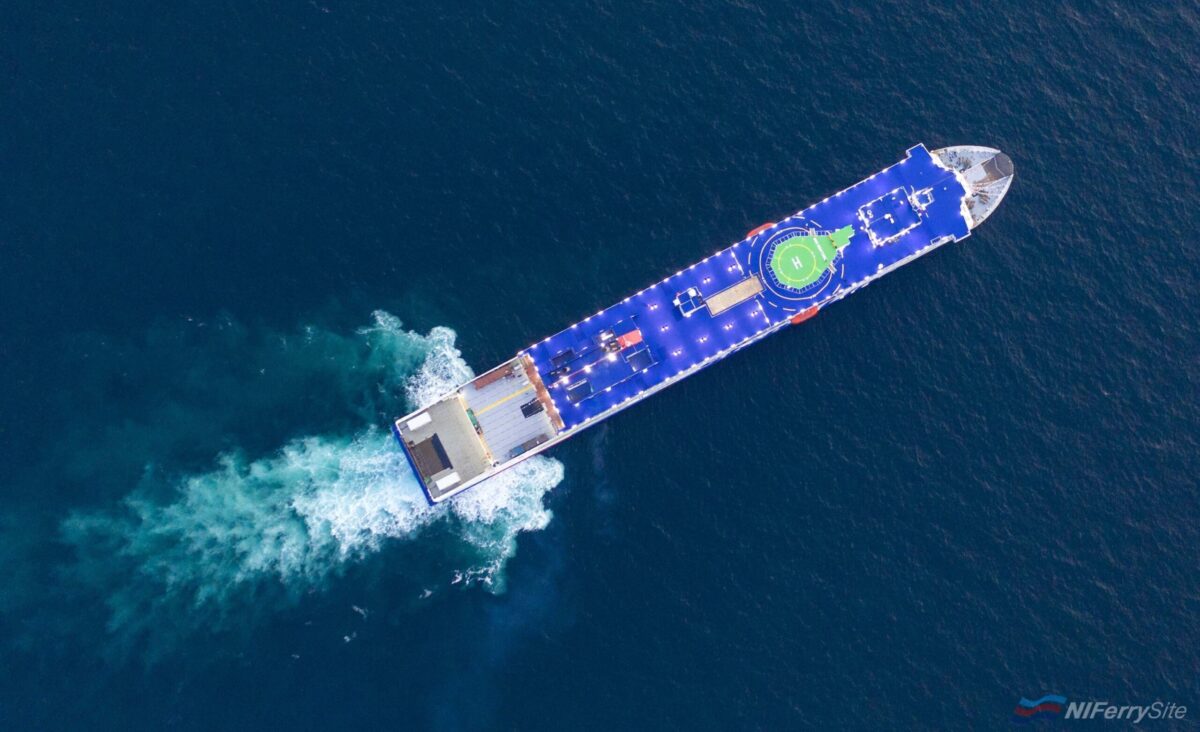

Stena Line’s “Stena Estrid” is the first of a new class of “Stena E-Flexer” ferries designed by and for Stena RoRo. She entered service for Stena Line between Holyhead and Dublin during January 2020, replacing STENA SUPERFAST X. “Stena Estrid” has capacity for 3,100 lane metres of freight plus 120 cars and around 1000 passengers.

STENA ESTRID was delivered to Stena Line at Weihai (China) on 15 November 2019. She left Weihai at the for the first leg of her delivery voyage on November 22. Her first destination was Singapore from where she will proceeded to Suez via Galle in Sri Lanka.

The brand-new ferry ultimately replaced STENA SUPERFAST X (now Corsica Linea’s A NEPITA) which served the Dublin route since March 2015. STENA ESTRID sails opposite STENA ADVENTURER for Stena Line on the Holyhead – Dublin route. She competes with with Irish Ferries’ ULYSSES, EPSILON / W.B. YEATS, and the DUBLIN SWIFT fast-craft on the same route.

At 214.5 m in length, STENA ESTRID became the longest ferry in operation on Irish Sea services when she entered service. Later in 2020 the second Stena Line E-Flexer, STENA EDDA, entered service between Belfast and Liverpool. STENA ESTRID‘s first commercial voyage was the scheduled 08:55 departure from Holyhead on 13.01.2020. Her departure was delayed until around 11am due to Storm Brendan.

The E-Flexer class was designed by Stena RoRo and Deltamarin for use by sister company Stena Line, as well as for charter to other operators. It is the product of a collaboration between Stena RoRo, Stena Line, marine architect Deltamarin, Stena Teknik, interior architect Figura, and Weihai Shipyard in China.

Designed to be environmentally friendly and efficient, Stena’s E-Flexer design has also be designed to be flexible and is suitable for numerous routes from short day crossings to overnight services. The project which would become E-Flexer was born in 2013 in response to a request from Stena Line for a new type of ferry which could serve as both a day and overnight ferry with the capability to easily interchange members of the class between routes.

Unlike the previous Stena SeaBird project, which was partially developed from Stena Seabridger mkII and then shelved in favour of E-Flexer, Stena E-Flexer is an all new design from the keel up.

Estrid?

Stena Line introduced a new naming scheme for their E-Flexer vessels, choosing to use Nordic names beginning with “E” with the usual Stena prefix. The names of the first three vessels were chosen via a staff competition.

According to Stena Line:

“The name Estrid is connected to Stena Line’s Scandinavian heritage. It is an Old Norse eastern-Nordic version of the name Astrid. Estrid is commonly found on old runestones and means ‘divinely beautiful'”.

Onboard Facilities

STENA ESTRID‘s passenger facilities are spread out over 4 decks as follows. Public facilities are housed on Deck’s 7 and 8, the latter of which also house approximately half of the passenger cabins. Deck 9 is a cabin and crew deck while Deck 10 is at the top of the ship and has a passenger accessible sun deck.

Deck 7

- Dedicated car deck with direct walk-through access to the passenger facilities

- Guest Services

- ‘Barista’ Coffee House

- Outlet Onboard (shop)

- ‘Happy World’ children’s play area and lounge

- ‘Taste’ restaurant with digital menu boards

- 2 x outside promenade decks with smoking section (port / starboard)

- 12 x heated dog kennels

- Male, Female, and Disabled Toilets and Baby Changing area

- Free Wi-Fi access

Deck 8

- ‘Stena Plus’ premium lounge (additional fee applies) with table service and dedicated toilet facilities.

- ‘Hygge’ recline lounge (additional fee applies).

- Interactive ‘Experience’ wall.

- The ‘Living Room’ lounge.

- ‘Truckers’ commercial drivers lounge and restaurant.

- Video games and gaming area.

- ‘Happy World’ children’s play room.

- The ‘Sky Bar’ bar and lounge.

- Two free movie lounges.

- A selection of passenger cabins including three deluxe cabins with balcony access and disabled cabin. All cabins are secured using a digital ‘VingCard’ system and have an infotainment TV system installed.

- Male, Female, and Disabled Toilets.

- Free Wi-Fi access .

- Outside deck space aft.

Deck 9

- A selection of passenger cabins including three deluxe cabins with balcony access and disabled cabin. All cabins are secured using a digital ‘VingCard’ system and have an infotainment TV system installed.

- The remainder of Deck 9 is occupied by crew accommodation areas and the navigation bridge.

- Free Wi-Fi access.

- Outside deck space aft.

Deck 10

- Sun Deck

Stena also released the following video about the Stena E-Flexer onboard experience ahead of the introduction of STENA ESTRID.

Virtual Tour

A 360 degree virtual tour has been published online showing an impression of STENA ESTRID‘s interior and layout. Please note that this is not a link promoted by Stena Line, and so may not reflect the final layout entirely. When taking the tour, click on the dots to “walk” to that area.

Click here to view the Stena Estrid tour in a new window.

Key Dates – Stena Estrid

| 11.03.2016 | Contract date1 |

| 05.04.2016 | Stena confirms that an order has been signed by Stena RoRo for 4 “E-Flexer” ferries plus four options at AVIC Weihai. The first of these would become Stena Estrid. |

| 26/08/17 | Steel cutting started |

| 02/02/18 | Keel laid |

| 16/01/19 | Floated out |

| Start of sea trials | |

| Sea trials completed | |

| 14.11.2019 / November 15.11.2019 | Completion / delivery to Stena RoRo |

| 13.01.2020 | Maiden commercial voyage (Holyhead – Dublin) |

| 03.04.2020 | Arrived at Loch Ryan Port (Cairnryan) for work to one of her main engines |

| 15.06.2020 | Resumed normal service on Dublin – Holyhead |

| 10.09.2020 – 22.10.20 | Overhaul relief on the Belfast – Cairnyran route |

| 01.2021 | Weekend sailings between Dublin and Cherbourg but weekday sailings remained between Dublin and Holyhead |

| 02.02.2021 – 24.05.2021 | Rosslare – Cherbourg |

| 25.06.2021 – 18.07.2021 | Operated a temporary service between Belfast and Holyhead |

| 26.10.2021 | Arrived at Harland & Wolff Belfast for scheduled overhaul |

| 02.2022 | Released sister-ship STENA EMBLA from the Belfast – Birkenhead route so she could cover Belfast – Cairnryan. |

| 28.03.2022 – 11.04.2022 | Covered the Rosslare – Cherbourg route |

Stena Estrid Technical Info

|

Name | |

|---|---|

|

IMO Number | 980729 |

|

Class |

Stena “E-Flexer” Passenger and Ro-Ro Cargo (Ro-Pax) ferry |

|

Building Yard |

AVIC Weihai, Shandong Province, China  (renamed China Merchants Jinling Shipbuilding (Weihai) Co. Ltd. prior to delivery) |

|

Design |

Stena / Deltamarin |

|

Naval Architect |

Deltamarin, Turku, Finland |

|

Project Management |

Stena Roro Deltamarin, Turku, Finland (EPCM) |

|

Interior designer and architect |

Figura Arkitekter, Gothenburg, Sweden |

|

Delivery and installation of public spaces, galleys, & cabins |

R&M (Rheinhold & Mahla), Hamburg, Germany / Weihai, China |

|

Galley Equipment |

Aluminox SA, Greece |

|

Contract date |

Ordered by Stena RoRo on 11th March, 2016 |

|

Hull Number | W0263 |

|

Start of Steel Cutting | 26/08/17 |

|

Keel Laid | 02/02/18 |

|

Floated out | 16/01/19 |

Completion / Delivery | November 14, 2019 / November 15, 2019 |

|

Certification |  Class: DNV GL Class 1C Type: 410 – Car FerryAdditional class notations: 1A Ferry(A) BIS BWM(T) Clean COMF(V-2) E0 Gas ready(D, MEC) Ice(1C) NAUT(AW) Recyclable TMON VIBR |

|

Owner |  Stena Line |

Operator |  Stena Line UK & Ireland, Holyhead, Wales |

| In service (Stena Line) | January 13, 2020 (Holyhead – Dublin) |

Route | Dublin – Holyhead |

Length Overall | 214.5 m |

Length BP | 202.5 m |

| Beam | 27.8 m (28.43 extreme) |

Draught | 6.4 m (design) |

Gross Tonnage | 41,671 GT |

DWT | 9,777 |

| Number of decks | 10 |

| Machinery | Main-propulsion package supplied by Caterpillar Marine including 2 x Caterpillar MaK 12 M43 C gas (Methanol or LNG) ready V12 4-stroke marine diesel propulsion engines built by Caterpillar Motoren Rostock GmbH, Rostock, Germany. Each main engine is coupled to a Caterpillar supplied gearbox (Renk RSHL-1120) (Note that to run with Methanol or LNG these engines will require upgrading to MaK 12 M46 dual-fuel specification – this has been allowed for in the design). 2 x Caterpillar (Berg) Feathering Controllable-Pitch Propellers MPP 1410f (PB58547). 3 x Wärtsilä 8L20 auxiliary engines, supplied by Wärtsila Finland Oy. 2 x Wärtsila WTT24 CP 2,400kW bow thrusters, supplied by Wärtsilä Netherlands (space provision is made for the addition of a third bow thruster should it be required in the future) 1 x S12A2-M(P)TA Emergency Generator, supplied by Mitsubishi Turbocharger and Engine Europe B.V. 1 x S12A2-M(P)TA Emergency Generator, supplied by Mitsubishi Turbocharger and Engine Europe B.V 2 x WE Tech 2,600kW permanent magnet shaft generators, with variable frequency drive (WE Drive) connected to a DC-link switchboard (WE Tech solution 4) for bow thrusters and Power Take Out (PTO) (WE Tech solution 1). 2 x “high lift” flap rudders, supplied by MM Ofshore, Germany Rolls Royce Steering Gear Mitsubishi retractable fin stabilisers Stena Estrid is gas ready and prepared for scrubber and catalytic converter installation should it be required. Spaces for additional equipment for these retrofits have been included in the design. |

| Access Equipment | TTS Marine AB |

|

Power |

25,200 kW |

|

Design Speed |

22 kts |

|

Passenger Capacity |

927 |

|

Crew |

73* |

|

Cabins | 175 passenger cabins, consisting of;

|

|

Vehicle capacity | 3,100 lane metres of freight (on decks 1, 3, and 5) plus 120 cars on an additional deck (Deck 7) |

| Lane Metre Breakdown | Deck 1 (lower hold): 345 lm approx. with 4.8m free height. Deck 3 (main freight deck): 1,320 lm approx. with 5.2m free height. Deck 5 (upper freight deck): 1,435 lm approx. with 5.2m free height. Deck 7 (car garage) has a volume of 1,800 m2 approx. |

| Vehicle Access | Twin-level-drive-through loading configuration with direct access via bow and stern doors on decks 3 and 5. Tilting ramps between deck 3 and 5, and deck 5 and 7 allow all decks to be accessed via single-level shoreside facilities. Access to deck 1 is via a 3.3m wide fixed ramp covered by a hatch. |

|

Flag | Cyprus (Limassol) [since 19.12.19] |

List of Key Suppliers

| Shipyard | China Merchants Jinling Shipyard (Weihai) Co., Ltd., China (Previously known as AVIC Weihai Shipyard Co., Ltd) |

| Design and Overall Concept | Stena RoRo, Sweden |

| Consulting Naval Architect | Deltamarin, Finland |

| Hull Design | Deltamarin, Finland |

| Tank Testing | MARIN, Netherlands |

| Technical Consultant | Stena Teknik, Sweden |

| Project Management | Stena RoRo, Sweden / China |

| Engineering, Procurement, & Construction Management | Deltamarin, Finland / China |

| Interior Architecture | Figura Arkitekter, Gothenburg, Sweden |

| Interior Design | Figura Arkitekter, Gothenburg, Sweden |

| Certification Society | DNV-GL, Norway |

| Outfitting | R&M (Reinhold & Mahla), Hamburg, Germany / Weihai, China |

| Additional Outfitting | Norgi Marine, Poland / Madden Marine, Belfast |

| Main Engines | Caterpillar Motoren GmbH & Co. KG (MaK), Germany |

| Gearbox and Controllable Pitch Propellers | Caterpillar Marine / Caterpillar Propulsion Production, Sweden (Packaged gearbox’s manufactured by Renk, Germany) |

| Variable-Frequency Shaft Generators and Electrical Switchboard | We Tech, Finland |

| Auxiliary Engines | Wärtsilä, Finland (Manufactured in China) |

| Bow Thrusters | Wärtsilä Netherlands B.V., Netherlands |

| Emergency Generator | Mitsubishi Turbocharger and Engine Europe B.V., Netherlands |

| Stabilisers | Mitsubishi Heavy Industries Marine Machinery & Equipment Co. , Ltd. |

| Rudders | MM-Offshore GmbH, Oldenburg, Germany |

| Steering Gear | Rolls-Royce Commercial Marine, Norway |

| Access Equipment (including all ramps) | TTS Marine AB, Sweden / Finland |

| Heating, Ventilation, and Air Conditioning | Novenco, Denmark / China (package includes chillers AHU, VAV cabin units, fans and all control systems) |

| Glazing | Saint-Gobain S.A., France |

| Galley Equipment | Aluminox S.A., Greece |

| Furniture | Various (including R&M; Capdell, Spain; vitra, Switzerland; and bespoke joinery by the outfitting teams) |

| Lifts | Kone, Finland |

| Lifeboats | Jiangsu Jiaoyan Marine Equipment Co., Ltd, China |

| Fast Rescue Boat | Jiangsu Jiaoyan Marine Equipment Co., Ltd, China |

| Davits | Jiangsu Jiaoyan Marine Equipment Co., Ltd, China |

| Marine Evacuation System | Survitec / RFD Beaufort, United Kingdom |

| Fire fighting Equipment | Minimax / Marioff |

| Simulator Training | Liverpool John Moores University Maritime Centre, England |

Concept and Design

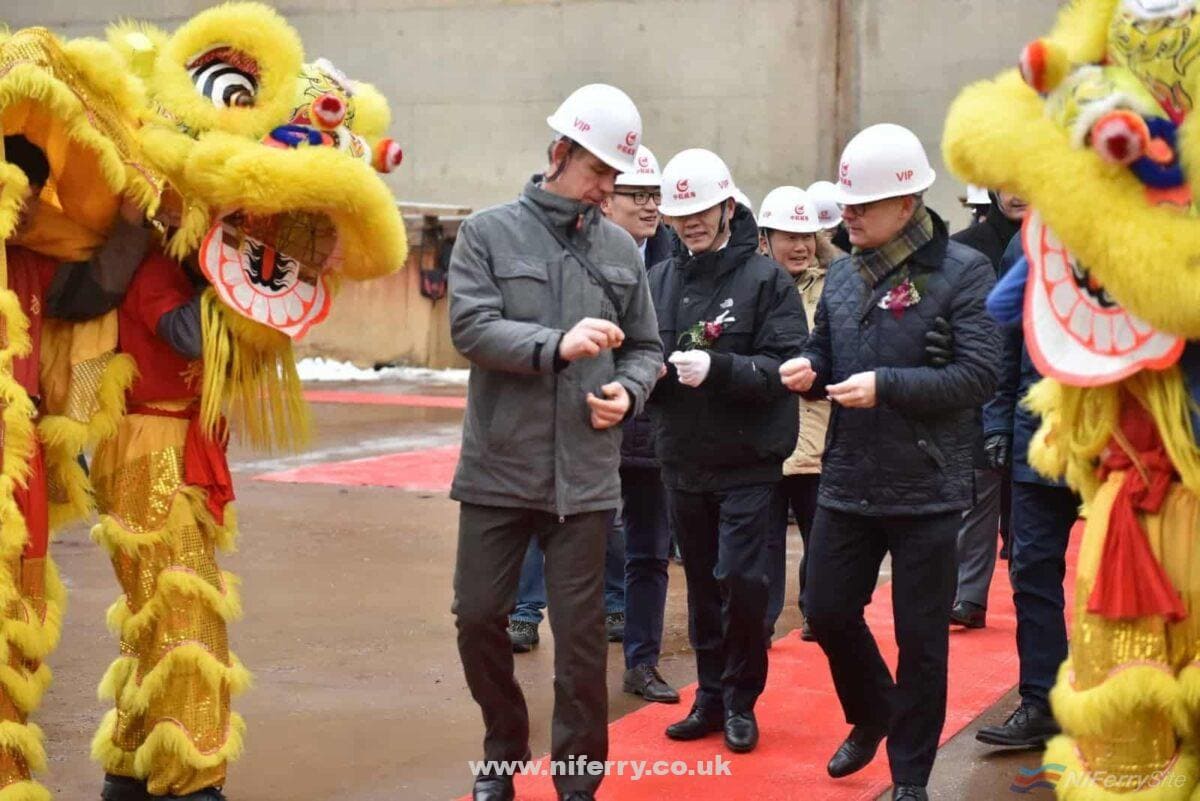

STENA ESTRID is the first Stena Line passenger ferry to be built in China. She is also the first ferry built by Weihai Shipyard for service in Northern Europe. Talks started with AVIC Weihai and other Chinese shipyards during 2015, with AVIC Weihai chosen due to their attitude and experience with international clients rather than for their ferry building experience. Another factor was that AVIC owned 80% of Stena’s chosen naval architect Deltamarin and so was well accustomed to working alongside them.

The Weihai facility itself was only completed at the end of 2008, when the company moved from an older site close to the centre of Weihai itself. The new shipyard was built on land reclaimed for the purpose and boasts two large building docks as well as extensive shoreside facilities.

The order for STENA ESTRID and three similar vessels was signed during March 2016 following around 2 years dedicated design work. Finland-based Naval Architect Deltamarin was chosen after winning a competition with another major consultant naval architect (said by some to be Knud E. Hansen) to produce the most efficient hull form.

After extensive tank tests at MARIN in The Netherlands, the Deltamarin design was found to be the most efficient at the design speed of 22 knots. The hull design is so efficient that Stena claimed E-Flexer will be able to attain 18 knots with just a single engine and propeller in use. This has since been proven in service.

Efficiency and Flexibility

From the start of the E-Flexer project, Stena had two big aims – to build a class of ferries that were more efficient and environmentally friendly than existing designs, and for the same series of ships to be able to operate across a wide variety of routes ranging from short crossings of only a couple of hours to overnight routes.

Flexibility

Traditionally ferries have been designed with a particular route type or market in mind, such as overnight or short sea routes. With the E-Flexer project, Stena wanted a design which could switch between routes with little to no conversion (such as that required with STENA SUPERFAST VII/VIII) needed. Stena have been building ferries for over 50 years, both for their own use and for the use of other companies. The E-Flexer project is the culmination of the knowledge and experience gained from five decades of operating and building ferries. STENA ESTRID is thus the product of over 50 years of Stena ferry building and operational experience.

The result of this experience, along with input from Deltamarin and interior architect Figura, is a ship which can operate in different accommodation modes depending on which route it is used on. Despite being able to load on two levels simultaneously, the E-Flexer design also incorporates internal tilting ramps between the vehicle decks. This maximises future deployment options by allowing all decks of STENA ESTRID to be loaded and unloaded from a single level if required. Also incorporated into the design is the ability to easily lengthen the vessels. Stena Line subsequently ordered two 239.7 m long versions of the E-Flexer design, but the standard length vessels can also be lengthened in the future if required.

Environmentally Friendly and Efficient

Together Stena and Deltamarin have come up with a ferry design which Stena claims has not just “best in class” fuel efficiency, but which they also claim has a significantly lower emissions footprint per freight unit than any other Ro-Pax ferry of similar size. In part this is due to the new hull design, but a number of other features incorporated into the design also boost the class’s environmental credentials. Economies of scale (vehicle capacity is around 50% greater than current standard Ro-Pax’s), hydrodynamics, and the other measures taken to increase efficiency mean that Stena expect CO2 emissions to be 25% lower per freight unit than existing Ro-Pax’s. This is despite the Stena Line ships burning conventional low-sulphur fuel oil and without the need for exhaust gas scrubbers.

Following her sea trials, the shipyard has confidently claimed that STENA ESTRID could burn 1300 tons less fuel per year than ferries of comparable capacity according to Chinese media. Stena intend for E-Flexer to be their last generation of fossil fuel powered passenger ferries. They have incorporated possible future conversion to burning methanol into the design, however.

The E-Flexer class is certified as “Gas Ready”, and STENA ESTRID and her sisters can easily be converted to burn LNG in the future if required. Indeed, two part-sisters being built for Brittany Ferries will burn LNG from delivery. Stena Line themselves are understood to be looking at alternatives to LNG due to that fuels own environmental trade-offs likely falling foul of future emissions legislation. Trials are already underway in Scandinavia, with STENA GERMANICA using methanol as fuel and STENA JUTLANDICA using battery power for part of her crossings.

The Caterpillar-supplied MaK M43 engines used in the E-Flexer class have a reputation for efficiency and reliability. They are the latest development of the design used in Irish Ferries ULYSSES, until relatively recently consistently one of the most reliable ferries in the world. They can also be upgraded to dual-fuel operation at a later date if required.

The Caterpillar supplied controllable pitch propellers are designed to be feathered to minimise drag when not required, allowing the ship to operate on just one engine and propeller at or below 18 knots. A feature trialled on STENA SUPERFAST VII to reduce fuel consumption, placing grids over the openings in the hull for the bow thrusters to reduce drag, has also been adopted.

Measures have also been taken to select lubricants and coolants which are biodegradable to minimise any potential impact on the environment. Paint containing the bio-repellent ingredient Selektope® has been specified for the underwater areas of the hull on all E-Flexer’s, including STENA ESTRID. This is designed to prevent marine growth which would create drag as the hull cuts through the water resulting in reduced efficiency.

STENA ESTRID‘s twin-level-drive-through vehicle loading configuration is designed for efficient loading and unloading and allows for quicker turnarounds. This means fuel can be saved during the crossing by running the ship at a slightly slower speed while still departing on time. Passenger cars are given their own garage on Deck 7 separate from freight, with passengers simply walking from their vehicle to guest services which is on the same level. This reduces the need for passengers to use staircases and lifts, and should speed up the return of passengers to their vehicles at the end of each sailing.

In common with other recent ferry builds such as Irish Ferries W.B. YEATS, STENA ESTRID and her sisters have LED lighting throughout which will significantly lower the electrical demands placed on the vessel.

A sophisticated electrical switchboard system designed for efficiency has been specified as part of an award winning package supplied by WE Tech which also includes a novel variable-speed, permanent magnet shaft generator arrangement. Like those on W.B. YEATS and other recent vessels these can respond to demand as required, but go further in increasing efficiency contributing to E-Flexer’s 25% reduction in CO2 emissions compared to other Ro-Pax vessels of similar size.

So efficient is this electricity supply system, that while the main engines are running the shaft generator attached to the main engine can produce all the electricity needed for the ships systems without the need to run diesel generators to supply electricity to the ship. The system can also supply electricity no matter what speed the main engine is running at.

Solar film is applied to all glazing on STENA ESTRID to reduce demand on the Novenco-supplied heating and ventilation system which in-turn will reduce load on the electrical system.

With such an efficient hull form, only two engines are required for the new Stena E-Flexer ferries in order to attain their design speed of 22 knots. This is despite the hull containing the additional weight caused by measures to attain either Ice Class 1C or 1A certification. Not only does this mean less fuel is used to fuel STENA ESTRID‘s engines, but by not carrying two additional very heavy engines there is a lot less weight to be pushed through the water.

The use of only two engines instead of the four generally specified in ferries is said to have been influenced by the simple design and success of the Visentini Ro-Pax series. That series, which is proven in service around the world, is known for its efficiency and also only uses two main engines.

Safe Return to Port

STENA ESTRID is the first new ferry built for Stena Line to the Safe Return to Port (SRtP) regulation. The regulation is designed to ensure that new passenger vessels of greater than 120m in length involved in an emergency can return to port under their own power with passengers and crew still safely onboard.

In common with other ferries compliant with the regulation such as W.B YEATS and P&O Ferries SPIRIT OF BRITAIN, a second navigation “bridge” is located onboard for emergency use. This is equipped with the essential equipment necessary to continue navigation in the event of an emergency situation.

The regulation requires a different approach to design, with many onboard systems duplicated in order to ensure the vessel can continue on her journey in the event of an emergency without the need to evacuate.

Other measures taken in the design process to ensure compliant ships can survive the numerous predefined scenarios include segregating engine compartments, specifying additional machinery to provide redundancy, and using specific routing for cabling and ducting.

Construction

Although the order for what would become STENA ESTRID was placed during Spring 2016, the first steel would not be cut at the shipyard until the following August. STENA ESTRID was only the second passenger ferry to be built by what was then the AVIC Weihai shipyard, and so there was much work to be done in order to prepare the shipyard for the E-Flexer project. This included building totally new facilities for the production of passenger accommodation spaces such as cabins.

In addition the yard already had two ferry orders to complete – a 860 passenger 2,160 lane meter ferry for service between China and Korea and a 2,430lm Ro-Ro freighter for Giovanni Visentini’s chartering business. As the first ferries built at the yard these projects would provide valuable experience for them in advance of beginning the construction of the E-Flexer series for Stena RoRo.

Modular Construction

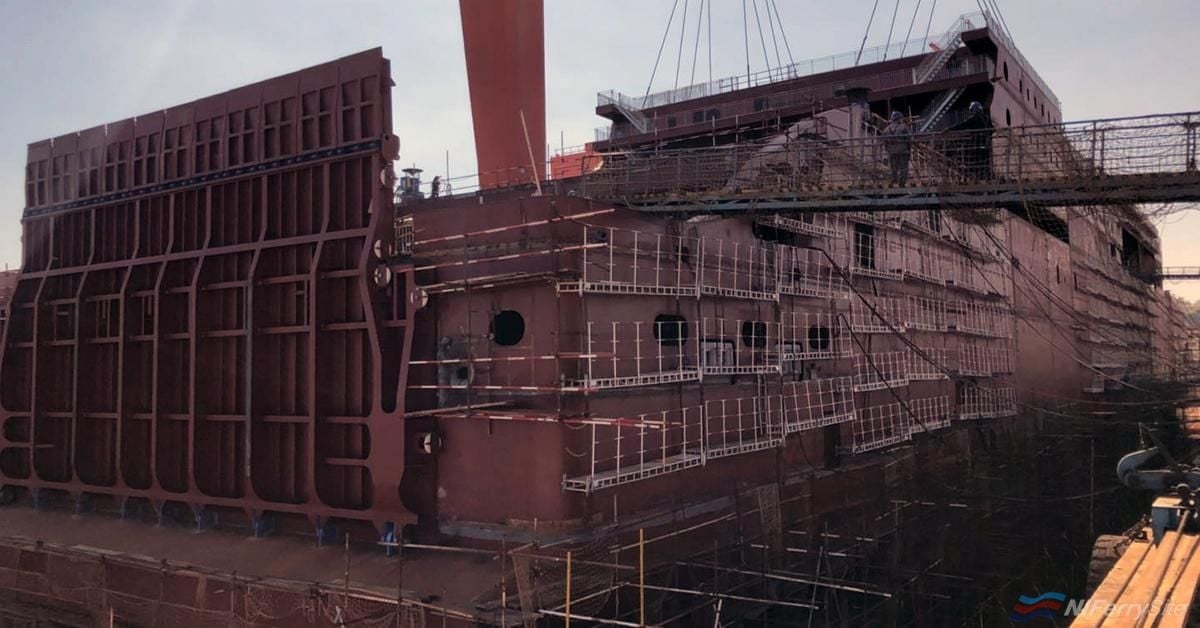

Once steel cutting began on August 26 2017 the construction of the “blocks” which would make up STENA ESTRID began. The hull and superstructure was to comprise of 304 of these blocks which were prefabricated since the start of steel cutting.

The keel laying ceremony of the first complete “block” of STENA ESTRID took place on February 2nd, with the others soon following and welded into place. By the end of September 2018, all of the 304 blocks which make up the hull and superstructure were in place in the building dock – just 13 months after steel cutting began and less than 8 months from the keel was laid.

Once “steel ready” the fitting of cabling and pipework began, as did the installation of propellers and rudders, ramps and the insertion of all the glazing (including a glass atrium) and insulation. On the January 16th 2019, STENA ESTRID was floated in a ceremony which was streamed live over the internet.

After floating, STENA ESTRID was guided by tugs onto the nearby outfitting pier at AVIC Weihai on February 20th. This was for completion of interior fit out by the yard and interior contractor Rheinhold & Mahla.

Stena Estrid Construction Gallery

Final Fit Out and Sea Trials

STENA ESTRID‘s fit out was completed alongside the outfitting quay at Weihai Shipyard. An international team of interior experts was assembled for the E-Flexer project with representatives from China, Sweden, Germany, Finland, France, and South Korea.

While ‘Estrid’ was being constructed, full scale mockups of cabins and public spaces had been built at the shipyard and signed off by Stena RoRo to be used as a reference for the final fit out. Continuing the modern modular approach to her construction, STENA ESTRID‘s cabins were prefabricated in a brand-new dedicated production facility on site before being hoisted on to the vessel. This climate-controlled cabin production facility is the first such facility in China.

Once onboard STENA ESTRID, the 239 passenger and crew cabins simply wheeled in to place (see picture above) and were connected to the ships electrical, plumbing, and HVAC systems. The prefabricated cabins were already fully fitted with bathrooms, wooden furniture, and heating and ventilation ducting. The cabin electrics and plumbing we also already fitted, and so were simply plugged into the grids on the ship once in place. Once all cabin units were in place the focus shifted to fitting out the public spaces based on the full scale mockups.

Stena Estrid Fitting Out Gallery

STENA ESTRID was observed leaving the shipyard on Thursday September 5th for initial trials lasting more than 24 hours. Further sea trials took place over three days during October 2019. The new ferry achieved 22.4 knots at design draft during her sea trials, slightly exceeding the design specification of 22kts.

Stena Line announced at the end of the month that STENA ESTRID had satisfactorily completed all of her trials. This followed reports in the Chinese media earlier in the same month that trials had been undertaken under the supervision of Stena RoRo and Stena Line, classification society DNV-GL, and the UK Maritime and Coastguard Agency (MCA).

These trials involved testing all of the ships onboard systems in both normal and emergency scenarios. Factors such as vibration and noise insulation were also tested by the team, with STENA ESTRID found to meet DNV-GL’s COMF-V and VIBR standards.

Stena Estrid Sea Trials Gallery

Following successful completion of her sea trials, STENA ESTRID returned to her building yard for some final touches prior to her handover/delivery to Stena RoRo and Stena Line.

Delivery

STENA ESTRID was delivered to Stena Line at Weihai on November 15, 2019. Following her delivery voyage from China and final preparations for service she is expected to enter service between Holyhead and Dublin in early-2020. On November 22, she left Weihai for Singapore under the command of Senior Master Mathew Lynch with a crew of just 27.

After arrival at Singapore, STENA ESTRID set course for Galle in Sri Lanka. Following her arrival at the Sri Lankan port on Wednesday December 4, she set course for Gibraltar where she was expected to arrive around the middle of December after transiting through the Suez Canal.

After transiting the Suez Canal and initially setting a course for Gibraltar, the destination was changed to Algeciras where the ship arrived on December 18th.

As well as taking on bunkers at Algeciras, the new ferry also collected additional crew who underwent training and familiarisation on the final leg of the journey to the UK. STENA ESTRID‘s home port was also changed from Cardiff (UK) to Limassol (Cyprus) while at Algeciras. This followed a decision taken centrally by Stena to re-flag their new vessels following political events in the UK.

Pre-service

STENA ESTRID arrived in Dublin for a brief berthing trial in darkness on December 23rd while en-route to Holyhead. She arrived in the Anglesey port the following morning, berthing at T3 beside the vessel she will replace STENA SUPERFAST X. She later relocated to the nearby Anglesey Aluminium Jetty where she remained over Christmas.

STENA ESTRID returned to Dublin on the morning of January 8th, spending most of the day at the Irish capital for drills and undergoing inspection by the authorities. In the following days Stena Line confirmed STENA ESTRID‘s maiden commercial voyage would be on January 13th in place of STENA SUPERFAST X. The latter ship then sailed for Belfast to cover the dry docking of STENA SUPERFAST VIII and STENA SUPERFAST VII. On the Saturday preceding her planned introduction STENA ESTRID was featured on BBC Radio and Sky News.

From the end of December 2019 until just ahead of her first commercial crossing, a fit-out team from Norgi Marine and Madden Marine were onboard the vessel. This was to make final touches and adjustments prior to the ships entry to service.

Included in this work was the reupholstering of the seats in the Hygge lounge with fabric, and the replacement of some windows and frames. These had been found to be weeping slightly during the lengthy maiden voyage.

Maiden Voyage and Early Service

STENA ESTRID made her maiden commercial voyage with a delayed sailing on Monday 13 January. The ship had been delayed due to heavy seas as a result of Storm Brendan.

With thanks to Stena RoRo, Diane Poole OBE @ Stena Line, Bronagh & Ciara @ Duffy Rafferty, and Christos @ Voyager ShipSpotting.

Stena Estrid FAQ’s

When was Stena Estrid delivered?

STENA ESTRID was delivered to Stena Line at Weihai on November 15, 2019. She left Weihai at the for the first leg of her delivery voyage on November 22. Her first destination was Singapore from where she will proceeded to Suez via Galle in Sri Lanka. After leaving Suez her next stop was at Algeciras, from where she proceeded to Holyhead via a brief call at Dublin for Berthing trials.

When did Stena Estrid make her first crossing?

STENA ESTRID‘s first commercial voyage was the scheduled 08:55 departure from Holyhead on 13.01.2020. Her departure was delayed until around 11am due to Storm Brendan.

Does Stena Estrid have cabins?

Yes, STENA ESTRID has 175 cabins available for passengers. This includes six deluxe cabins and two cabins specifically designed for passengers with physical disabilities. You can view photos of the cabins in the gallery here.

How big is Stena Estrid?

STENA ESTRID is 214.5m long and has a beam of 27.8m.

How many decks does Stena Estrid have?

There are a total of 10 decks on STENA ESTRID. This includes three passenger decks (plus a sun deck) and four vehicle decks. For further information on these facilities and plans of the layout of the passenger decks, please visit our dedicated page here. There is room for 3.1km of freight on three decks (1, 3, and 5) plus 120 passenger cars in their own dedicated garage on deck 7 beside the passenger accommodation. For further technical information including the access arrangements for vehicles, see STENA ESTRID‘s technical information page.

What is the Hygge lounge?

The Hygge lounge is a premium reclined seat quiet lounge. For an additional supplement paid at the time of booking or at the onboard kiosk (subject to availability), passengers get their own seat in the lounge with a dedicated reading light, USB and power socket, and a table. Children under 8 are not permitted in the Hygge (pronounced hue.gah) lounge. The concept first appeared on Stena Line’s Belfast – Cairnryan route and was later expanded to Dublin – Holyhead and Belfast – Birkenhead.

Further Reading and Sources

- Holtoff, P. (2019). Shippax Info March 19, pp. 7-23

- https://www.ship-technology.com/projects/stena-e-flexer-ropax-ferry/

- https://www.stenaroro.com/cases/newbuild/

- https://www.niferry.co.uk/stena-e-flexer-new-stena-ropax-ferries/

- DNV GL

Original version posted November 13, 2019

- Vesselregister.dnvgl.com. 2020. DNV GL Vessel Register. [online] Available at: <https://vesselregister.dnvgl.com/vesselregister/vesselregister.html> [Accessed 19 November 2020]. [↩]